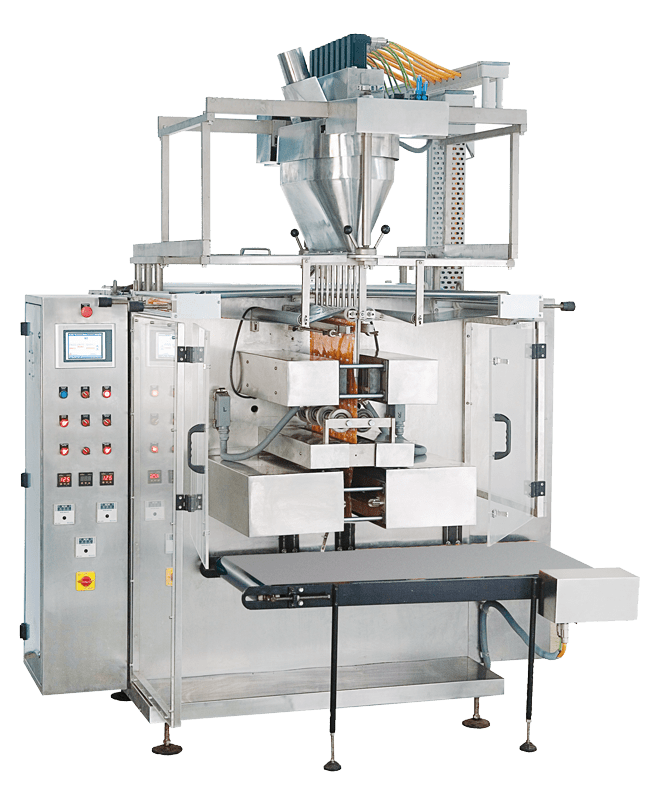

MB 150 (Multilane Sachet)

Our flat sachet packaging machinery is prepared for any type of product, offering an easy & fast format change with low maintenance, reducing downtime at the production line. With a simple & compact design, it is built up with high resistance & durable components. This model has been a work horse in the Indian Pharmaceutical sachet market for over 20 years, providing flexibility without compromising on output. It is also GMP compliant.

Slide Filler

Free flowing Pharma Powders, Granules, Sugars, Salt, etc.

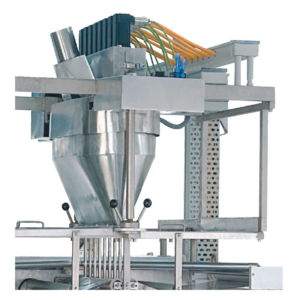

Auger Filler

Non-free flowing sticky powders like Milk, Turmeric, Pharma Powders, etc.

Liquid Filler

Liquid products like, Shampoo, Cough Syrup, Coconut Oil, Liquid Detergent, Ketchup, etc.

4 TRACK: UPTO 160 PPM

6 TRACK: UPTO 240 PPM

8 TRACK: UPTO 320 PPM

10 TRACK: UPTO 400 PPM

– W: 40-100 MM

– L: 40-200 MM

8 TRACK:

– W: 40-75 MM

– L: 40-200 MM

10 TRACK:

– W: 40-60 MM

– L: 40-200 MM

* Special size available on request

L: 1600 MM

H: 1800 MM

Features

- GMP construction

- PLC based control system

- 7″ Touch HMI

- Powered film unwind

- Film tension control

- Photo eye for film length control

- Auto web alignment

Utility

- Compressed Air: 700 lpm at 6.0 Kg/sq.cm.

- Power: 6KW

- Design sealing pattern

- Auto carton integration

- Complete flame proof version available

- Can be upgraded to ATEX for flammable products

- Can be upgraded to 21CFRpart11

- Inkjet/Laser printer integration

- Camera inspection OCR & BCR with rejection

- CE & UL certification available

- Jacketed hopper with hot water/oil recirculation system

- Splicing table for easy film change-over